Paver block making machine is a kind of equipment that is used for making paver blocks. It can be divided into two categories, namely, dry process and wet process. Dry process is the traditional way for producing paver blocks, but it has some disadvantages such as high cost and low efficiency. Wet process is more advanced than the dry one. It has higher production capacity and lower cost than the dry one.

Paver blocks are made by mixing sand, cement, aggregate and water together. The mixture is then pressed into a mold and then cut into individual pieces. Paver block making machines come in different shapes and sizes depending on the type of paver block they are being used to make.

Paver blocks are often used for walkways, patios, and driveways because they are durable and easy to use. They are also used for other things like building foundations, retaining walls, and drainage systems.

1. Quality of materials to be used in the concrete block and paving block moulds:

The longevity (amount of moulding) of the machines and mould to be use by the manufacturer, the intended products quality (dimension conformity to standards, durability) vary according to the quality of materials in the mould.

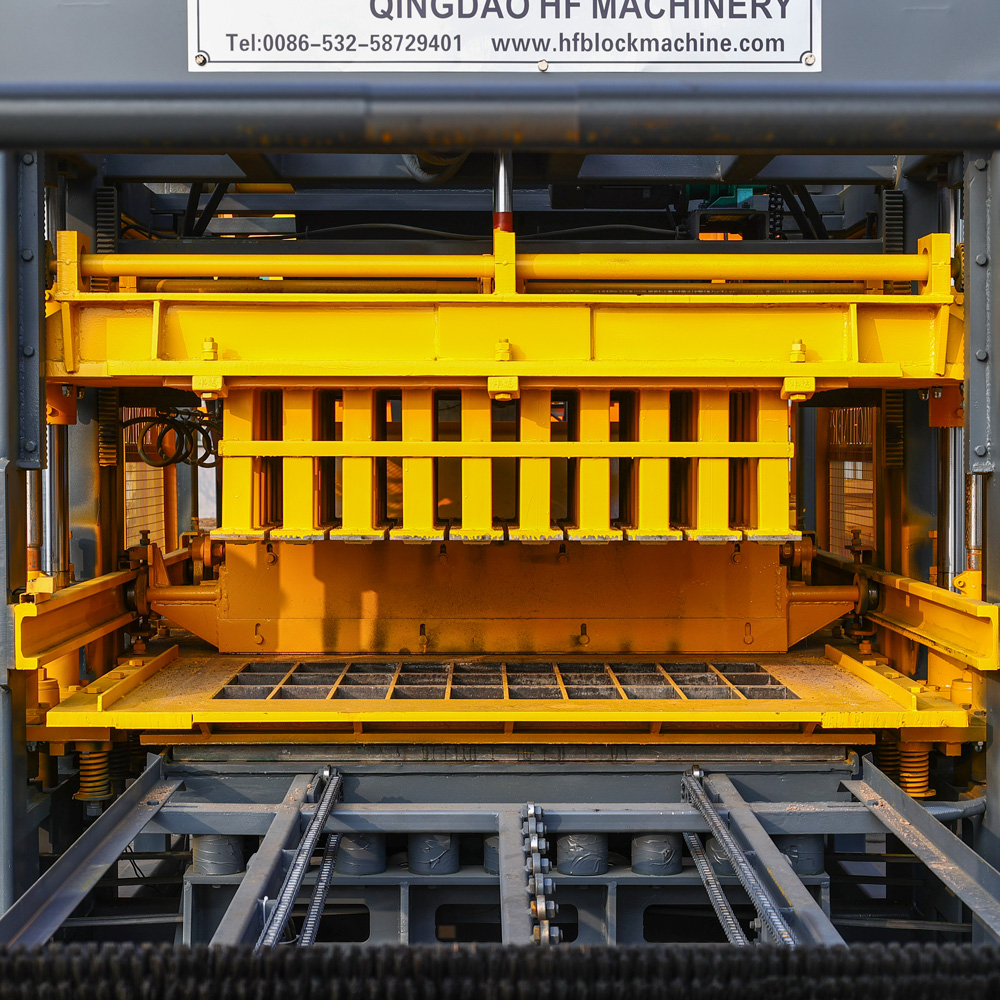

As it is known, the raw materials aggregate used for the production of concrete block and paving block etc. causes corrosion in the mould after a length of time. The use of high-quality steel increases the mould’s resistance to corrosion. The pressure applied by the machines on the moulds (may vary depending on the machine, e.g. 120 bar) significantly affects the durability of the mould. Therefore, in order to prevent the loss of labour and quality of product the alloy of the steel use for the mould to be bought must be of good quality.

The moulding of the steel, carbon and other substances contain ratio, the way through which it’s found, the method of obtaining the steel, the site where the materials will be used and its duties are features to be given special attention.

2. Concrete Block and Paving block Mould Workmanship:

One of the most important factors to be considered during the mould production phase is the quality of the product. Thanks to developing technologies, many productions are now done by machines made with millimetric measurement.

At this point one of the problems that come forward is the experience of the personnel using the machine and knowledge in solving problems related to the equipment. In addition, although production is made by machines, in some processes, especially for the production of concrete block moulds, the metal parts cut by the machines must be welded manually by the personnel.

In this process, the right equipment, workmanship and experiences are important factors. Wrong welding decreases the quality of the product. Losses occur due to product dimensions, product image, cracks in the product obtained and printing quality problems.

In conclusion, the degree of conformity of the product and its parts with the strict standards determined by the designer is known as quality, and these standards are directly related to the raw material, dimensions, tolerances, appearance, performance, reliability and other measurable properties of the product. The only way to achieve quality is quality equipment, manufacturer experience, and a competent staff.

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

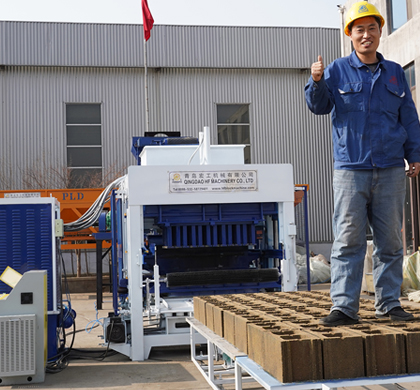

We will contact you within 24 hours.